|

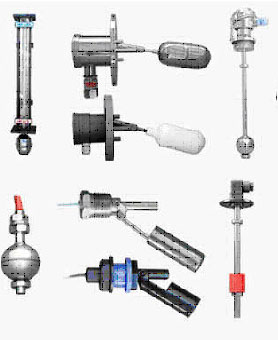

Level Switching sensors are made out of various materials available today in the market catering to vast range of chemical applications.

The naming of the product is mostly prefixed with the type or principle of operation. This sensor usually generated a signal of continuity and is to be connected to a controller for alarm / relay action to activate a electrical appliance.

|

| |

| (1) Magnetic Float Switches |

|

|

|

A Mounted Magnetic Level Switch is normally a simple device that monitors the liquid level in a tank and sends a trip signal to another device such as a Pump to protect it. These Level Switches are used for Pump protection, Cooling Circuit protection, high & low level alarm and general level monitoring. |

|

| |

|

| |

| (2) Capacitive Level Switches |

|

| |

Capacitance techniques are capable of operation at extremes of temperature and pressure. They work well for materials that won’t leave a coating. Usually only a single tank penetration is required. |

|

| |

|

| |

| (3) Vibrating Fork Level Switches |

|

| |

The electronically stimulated fork vibrates at its mechanically resonance frequency of about 125 & 400 Hz when the fork is free of the service material. The resonance is caused by the piezoelectric crystals. One of the piezo crystals produces a small voltage which is transmitted to the switching amplifier. If the fork is covered by the bulk material, a damping effect is produced and the piezo crystal does not produce the environment, voltage and the amplifier will switch and a corresponding signal output is actuated. Can be configured either for High or Low Level |

|

| |

|

| |

| (4) Radio Frequency Level Switch |

|

| |

RF Admittance is next generation capacitance as such it is by far the most versatile technology for continuous level measurement. It can handle a wide range of process conditions anywhere from cryogenics to approximately 850 o C and from vacuum to 10,000 psi pressure. Aside from the electronic circuit technology, sensing element design is very important to handle these process conditions. There are no moving parts to wear, plug, or jam. |

|

| |

|

| |

| (5) Vibrating Rod Level Switch |

|

| |

Vibrating Rod Level Switches provide reliable level detection of powders and bulk solids. This compact, integral switch is suitable for high or low level detection in hoppers or silos. |

|

| |

|

| |

| (6) Conductive Level Switch ( for conductive liquids) |

|

| |

These are available in solid probes for smaller lengths and suspended or flexible probes for larger lengths. Applications suits to medias with conductivity as the name of the product signifies the principle of operation |

|

| |

|

| |

| (7) Rotary Paddle Level Switch ( for powders and granules) |

|

|

Rotating Paddle Series type Level Switch for level detection of free flowing powders / granules / solids in the hoppers, bins and silos.. Dust seal assembly to prevent ingress of fine powder and high temperature stand off available. |

|

| |

|

| |

| (8) Displacement Level Switch |

|

|

Top mounted displacer type level switches offer the industrial user a wide choice of alarm and control configurations. These units utilise a simple buoyancy principle and are well suited for simple or complex applications, such as high level alarm or control of multiple pumps and alarms. Displacer switches are both reliable and cost effective. |

|

| |

|

| |

| (9) Cable Balloon Float Switch |

|

| |

A change in liquid level causes the float to tilt up or down and in the process move the steel ball to operate the micro switch plunger to close or open an electric circuit, which in turn operates auxiliary devices like alarm, solenoid valve, pump etc. This float with attached cable is combined with an adjustable stopper, support pipe or suspended ballast to provide 3 different type of constructions in vogue in process industry.

- Micro Switch used as contact output, Switching capacity 10A/250VAC, 15A/250VAC can drive the submersible pump directly.

- HAR rubber cable is lasting and can be used in any climatic condition. Simple, maintenance free, can be applied in Waste/Pure water.

- Cable length is adjustable

|

|

| |